As part of the refurbishment of the sludge incineration line at the Strasbourg wastewater treatment plant, the project faced a triple challenge: maintaining full plant operations during construction, managing high technical density (430 pieces of equipment, 1,100 instruments, over 3 km of piping), and working within an extremely limited footprint of just 2,100 m².

To address these challenges, a structured and collaborative BIM strategy by Suez as the lead representative of the consortium, was implemented from the outset, built around a shared digital environment powered by Dalux. Within this framework, Vcad was integrated as a key complementary tool, supporting data exploration and analysis across all project phases.

Design phase: ensuring model/process coherence

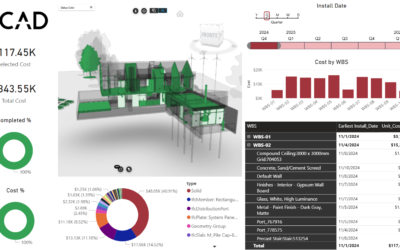

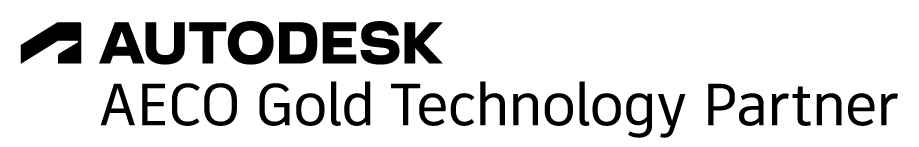

Vcad was used to conduct cross-checks between the 3D model and the P&IDs, verifying pipe diameters (DN), equipment presence, and functional logic. This dynamic and visual analysis significantly enhanced technical accuracy before moving into execution.

This view helps to validate 3D models with thousands of objects by using colours to represent the state of the elements. In a few minutes we are able to see the discrepencies between the P&ID and the 3D models.

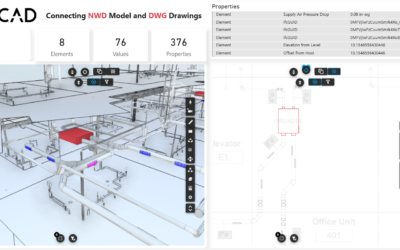

Construction phase: defining functional scope and responsibilities

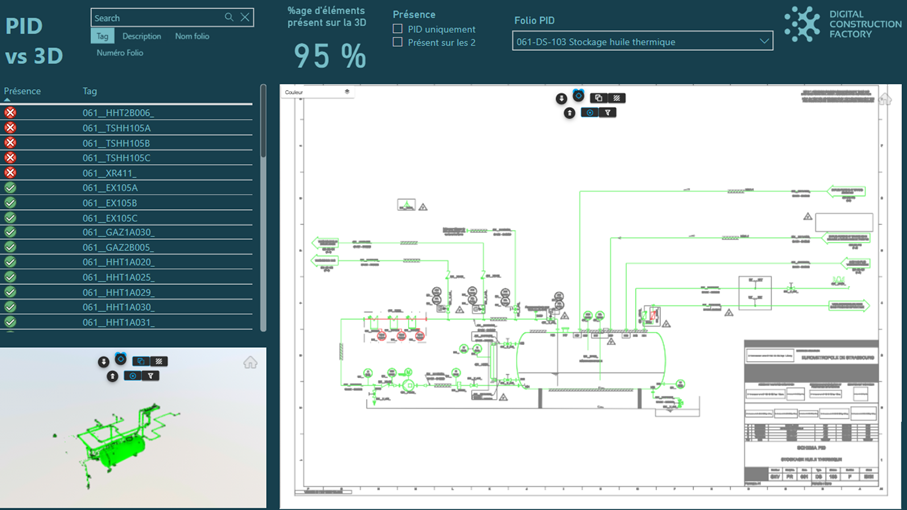

Construction of complexe industry projects needs a clear split of work and workbreakdown structure.

Vcad enabled the visualization of subcontractor scope boundaries and helped represent the functional breakdown of the plant into systems and subsystems (process sets). This improved clarity for planning, interface management, and field execution.

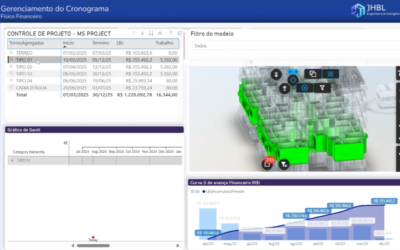

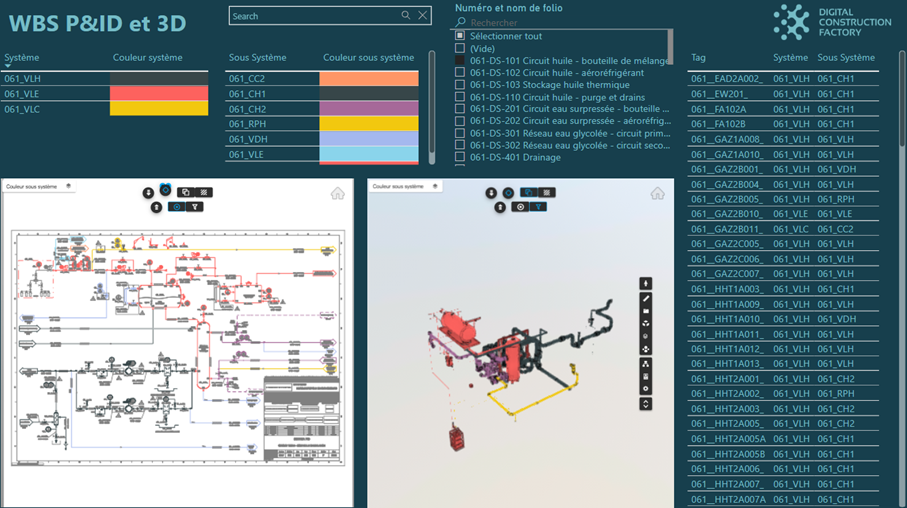

Progress tracking and HSE: linking field data to the model

One of the key strengths of the project was the combined use of Vcad and Dalux data. This dual-platform strategy allowed:

• Real-time tracking of equipment installation, using field inputs from Dalux forms linked to elements visualized on the P&ID and 3D trough Vcad.

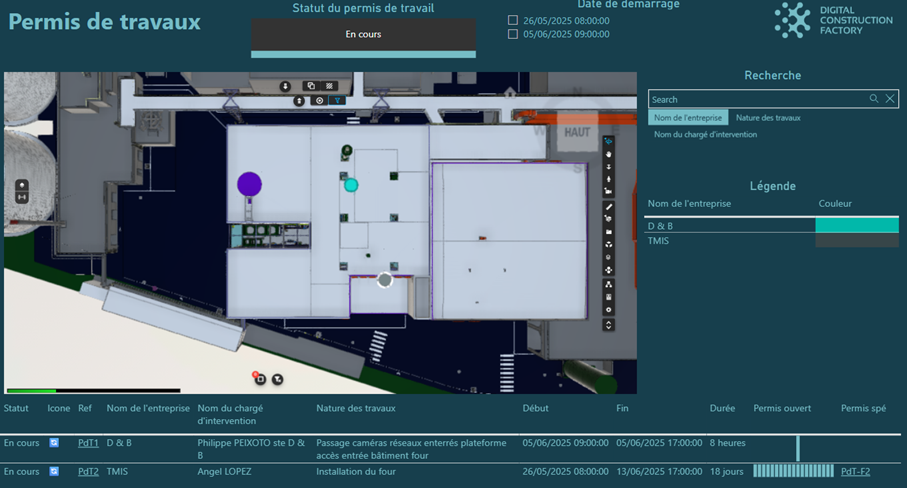

• Work permit creation and safety coordination, by associating intervention zones (identified in Vcad) with operational rules and HSE workflows created in Dalux. VCAD allowed us to manage the co-activities on site.

This combination offered a fluid connection between site activities and structured data, making model-based project management both intuitive and traceable.

Conclusion

By intelligently linking functional data (P&IDs) to geometric data (3D models), and by connecting model-based visualization (Vcad) with field operations management (Dalux Field), the team created a robust digital framework to manage a highly complex project. This approach enhanced quality, coordination, safety, and above all, made project data accessible and actionable for everyone, from the design office to the field.

Thanks to Sylvain Lemasson from Digital Construction Factory for sharing this contribution to the practical implementation of the digital workflow. His input was key to leveraging Vcad and Dalux effectively in day-to-day site coordination and data-driven decision-making.